Additive Manufacturing aka 3D Printing Benefits

On Demand End Use Parts

Topology Optimisation

Mass Customization

Responsible Manufacturing

Geometric Freedom

Optimize Resources

Save Money

Save Time

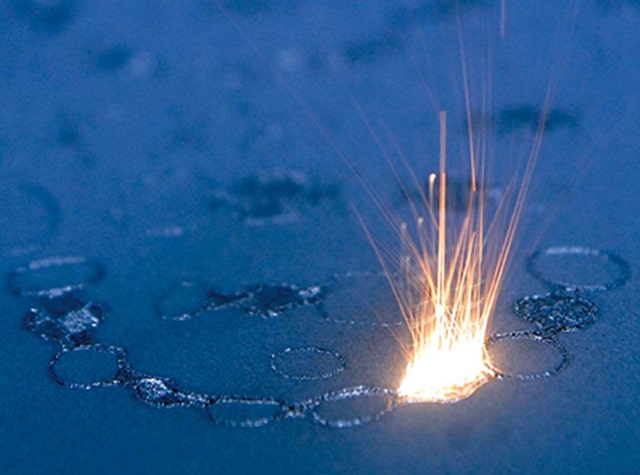

Future Ariane Propulsion Module Simplified

“Mission Critical” perfectly describes the Class 1 components used in the aerospace industry. Missions costing hundreds of millions depend on these components. Accordingly, engineers are constantly seeking to develop components of the highest quality, functionality, and robustness while simplifying the manufacturing chain and reducing the number of individual elements.

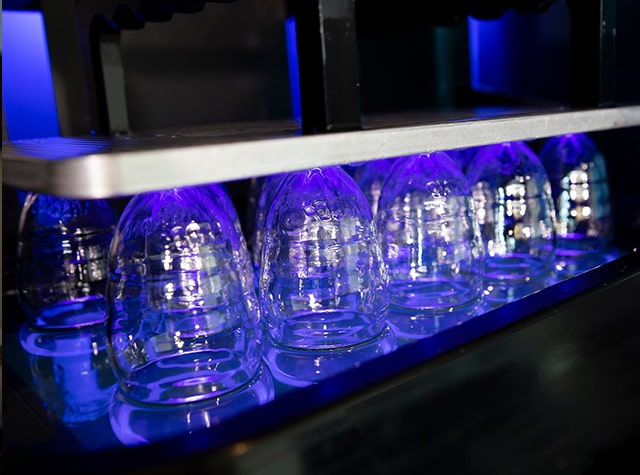

Metal 3D Printing for glasses frames

The eye is the point at which the soul and body merge.” It is not clear whether the designers from Hoet oriented themselves on this quote by dramatist and lyricist Christian Friedrich Hebbel. But looking at the classic and inimitable design of the new collection, one could easily think so. This eye-catching range was made possible by Additive Manufacturing technology.

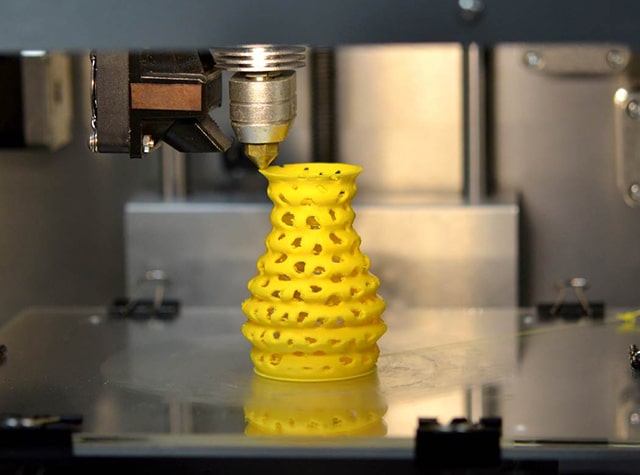

Additive Manufacturing Enables Design

One example of successful product development and production using additive manufacturing is the DHDG adaptive gripper. It has become an inherent part of Festo‘s production range and is manufactured on a FORMIGA P 100 supplied by EOS. Its structure is adapted from a fish fin and has two flexible bands which form a triangle to converge at the top.